Equipment Health Monitoring:

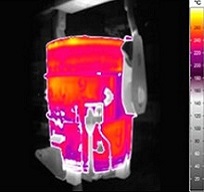

Ladle and Torpedo : Position by RFID and Health by Thermal Imager

Thermal imagers offer real-time monitoring of the ladle or torpedo's temperature distribution, allowing operators

to identify hotspots, thermal gradients, or potential refractory lining issues. This helps prevent damage to the Ladle/Torpedo and ensures

the integrity of the molten metal during transportation. By detecting abnormalities early on, operators can take immediate corrective actions,

preventing costly equipment failures and production delays.

Position tracking with RFID technology enables accurate and automated tracking of ladles or torpedoes throughout the production process. RFID tags attached

to these assets can be read and tracked using RFID readers placed at various checkpoints. This allows for real-time visibility of their location, movement,

and monitor TAT : Turn Around Time of these ladles or Torpedo. With this information, operators can optimize material flow, Lead time of metal requirement, schedule maintenance activities, and ensure the timely availability of ladles or

torpedoes at different process stages.

By combining thermal imaging and RFID position tracking, industries can achieve comprehensive monitoring and control. This integration enables proactive maintenance, as potential

issues identified by the thermal imagers can trigger automated alerts or maintenance schedules,improving the overall reliability and lifespan of the ladles or torpedoes.

Furthermore, the combination of ladle/torpedo health monitoring and position tracking enhances safety. Operators can remotely monitor the assets' health and position, reducing

the need for manual inspections in hazardous environments. This minimizes the risk of accidents and improves the overall safety of the workforce.

Furthermore, the combination of ladle/torpedo health monitoring and position tracking enhances safety. Operators can remotely monitor the assets' health and position, reducing

the need for manual inspections in hazardous environments. This minimizes the risk of accidents and improves the overall safety of the workforce.

Overall, Ladle or Torpedo health monitoring and position tracking offers improved asset reliability, proactive maintenance,

optimized material flow, enhanced safety, and streamlined production processes, leading to increased efficiency and cost savings.